This website is a cache of a forum thread on smartcar451.com that outlines my conversion of a 1993 Honda Del Sol to electric power! If your on dialup, you should'nt be! All the content is in one place down below. As time permits a REAL website should be made. If you wish all the pictures and more can be listed in a gallery here:Honda Del Sol EV conversion

Posted: Sun May 22nd, 2011 05:28 am

I have thought about it for a couple months now. The smart car fits my "around town" lifestyle pretty well. With the exception being my month long trip across the country.

I say this because I am convinced an electric smart car can be made much cheaper then the upcoming smart ED. Along with that, I also think the parts are out there to make it a superior vehicle.

I mention this because I am seriously considering going to a workshop designed around converting cars to electric.

I have followed the EVTV website for a while now and they are top notch group of people. Everything is documented in video form to explain and discuss the problems that do arise.

When I heard they where going to have a workshop with a limited number of people and vendors in attendence I thought "What a interesting way to spend 4 days!".

I would go there to gain knowledge to perhaps one day convert my own smart car to electric. The website already has a smart car they plan to convert to electric but the last I heard they are waiting on China to hopefully utilize hub motors to power the vehicle.

The main website is at: http://www.evtv.me

And the event is at: http://www.projectooc.com/evtv/evccon_itinerary.php

I will report back my decision.

5/28/14: To recap this thread. I ended up converting a 1993 Honda Del Sol to electric power. In this thread you will find my progression through the process. This project will continue to evolve as I find things to make "better".

The car is driven daily and is alot of fun! I gallery of just some of the pictures is located @ http://www.techvelocity.com/delsolgrouped/

Posted: Fri Jun 24th, 2011 02:38 pm

OK, I am officially doing this! I just registered today and am pretty excited about the possibilities.

Posted: Thu Aug 4th, 2011 03:32 am

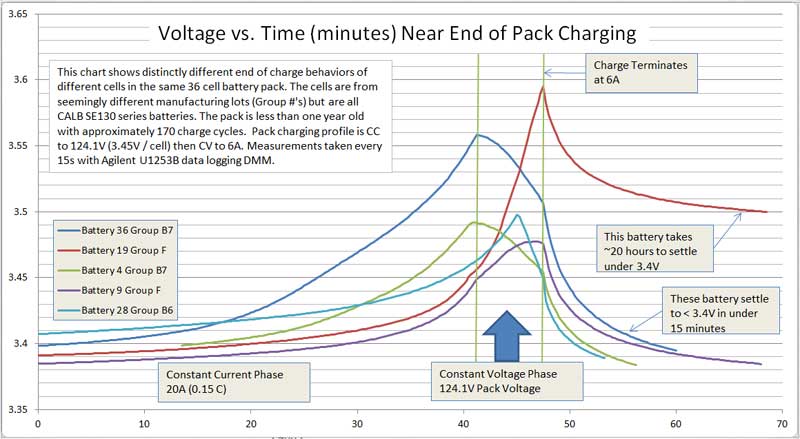

They have an excellent show up this week involving battery testing! Check it out if you have a spare hour OR TWO!

Posted: Tue Aug 16th, 2011 03:38 pm

Wow!,

I have'nt even attended this event yet but the amount of information I have found on the internet is amazing. The more I see what makes a good electric car, the more I am actually pushed away from using the smart car as my first canadite. The required specs for a good EV are the following: Lightweight, space for batteries, manual transmission. With that in mind I cannot find one that meets all the specifics. My idea is either a Cadillac Catera or a Lincoln LS. The Caterra was never offered with a manual transmision (but it was overseas as an Opel Omega) but the Lincoln LS was in 2000-2001 but is heavy @ 3700-3800lbs. So its a matter of personal preferrence as to what car I chose. Having owned nothing but GM for many many years I am all to familiar with the types of cars they produce. So having said that, the best case scenario would be to reduce weight rather then convert an automatic car to stickshift. So my choice at this point is an 00-01 Lincoln LS V6 stickshift. I am not even sure at this point I can build a superior car to an OEM for the price. The biggest cost involved is still going to be the batteries. This is going to be fun!

Posted: Sat Aug 20th, 2011 07:49 am

I am probably just "spinning my wheels" until I actually attend the event, but..... I have been looking online and to get the 200-220ah 3.2v cells in enough quantity to have a 75 mile range I am looking at $11000.00! At the rate things are moving in the EV world I think it would be foolish to drop that kind of cash on something that will surely be bested not 3 months later. So my plan at this point is to build up a car with a min spec battery pack. Everything else will be overbuilt, good motor, good controller, good charger, etc. Then a year down that road replace the batteries with a larger and better pack.

Posted: Fri Sep 30th, 2011 03:06 am

Back

from the event! What a fantastic time. A lot of the information I was

already familiar with. But if I did have a question, a representative

from the company was there to answer them.

I am confident this event will go down as a turning point for

electric vehicles.

I

am coming at this full speed. Many of the contacts I made at the event

are ALREADY sending components for the build. This before I even have a

car!

I may comment further on the event but having driven from my overnight stay in Oklahoma to Ca straight through, sleep is in order.

Posted: Thu Oct 6th, 2011 12:02 pm

Things are falling into place.

When

it comes to EV's the motor controller is the "brains" of the car. Think

of it as a regular gasoline engines ECU/PCM. When it came to make a

decision on the brand I can already tell you I was a little biased

towards the evnetics unit. And as a sponsor of the EVTV show I watch I

feel the need to support them. I have read extensively on the Soliton1

controller. Everyone I have talked to loves the unit. It is HIGHLY

configureable and the support evnetics offers is top notch, both online

and on the phone. I was fortunate enough to meet Sebastien Bourgeois

from evnetics at the EVCON event a couple weeks back. What a stand up

guy! He answered all my questions (even dumb ones) with ease.

Because

of this and even before I have a car picked out, I have purchased a

Soliton1 controller for my build. It's TOTALLY overkill for my project

but I figure it is better to understress then overstress the components.

Read all about it here: http://www.evnetics.com/index.php/soliton_specs

Posted: Sat Oct 8th, 2011 02:51 pm

I have been busy and until I get the time to get some of my

own photos of EVCON up, check these out!

http://gas2.org/2011/09/27/electric-vehicle-conversion-convention-mega-gallery/

Posted: Fri Oct 14th, 2011 03:01 pm

The controller came yesterday. I am going through the instruction booklet now which is quite nice! Still need a car!

Posted: Thu Oct 20th, 2011 09:17 am

After

removing the controller from the box I noticed what I thought to be a

plastic retaining nut on the ethernet port to be cracked and missing. I

contacted EVnetics and was surprised to learn this was the actual port

that was broken in shipping thus requiring the controller to be

returned to FL. I guess it was better to find this out now. EVnetics

has been GREAT about this issue and am awaiting a call tag for pickup.

On the car hunt front things are looking up. I am seeing a car tomorrow afternoon. If that does'nt pan out I am either going to TX or FL for the purchase.

Posted: Thu Oct 27th, 2011 03:24 pm

OK here is a breakdown of cars I have been seriously

considering.

01 Lincoln LS stickshift (somewhat rare but obtainable)

1993 Honda Del Sol base model stickshift

1999 Mazda Miata

All have pro's and cons.

The

Lincoln is heavy. The Del Sol, everyone modifys and its not usually

tastfully. The Miata is looking like the best scenario so far.

I have looked at 8 Del Sol's and not a single one I would consider purchasing!

Posted: Thu Nov 3rd, 2011 01:29 pm

The controller is due back tomorrow. They replaced the broken

(in shipment) ethernet port and its as good as new.

I am still looking for the right vehicle. Its the most trouble I have ever had finding a car!

Posted: Sat Nov 5th, 2011 02:36 pm

Happy days!

Just when I was getting fed up, I found a car!

Earlier

in the day I had seen a 95 Miata that was in OK but not perfect

condition. I made an offer and the guy did'nt even counter it and left.

Then

when I got back home I looked on my cell phone on craigslist for more

Miatas. Nothing I had'nt already seen. So I decided to look for Del

Sol's again to see what was out there. I saw a nice 1993 Del Sol with

72k miles in great condition minus a couple little dents and a tear in

the driver seat bolster. I had totally missed this ad because I had

been looking for Miata's. The ad was 5 days old and I was happy to hear

that the owner still had it! I hot footed it up to Torrance about 50

miles away and looked it over. I made an offer and the guy quickly

accepted (which leads me to believe I should have offered lower) but at

this point in the game I was over haggling and just happy to find a car

that fit the bill.

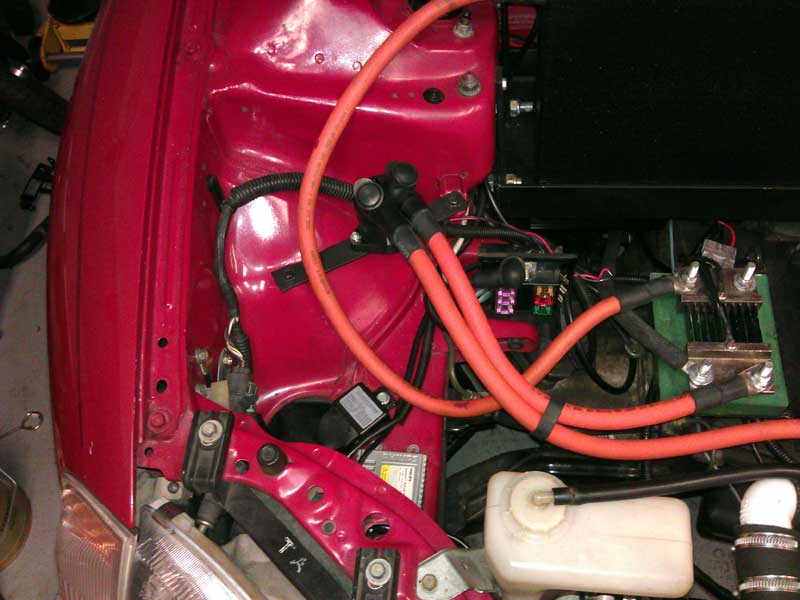

This picture was taken

with a cell phone camera and thus the red's appear pinkish. I assure

you however the Del Sol is fire engine red. Going to take a couple days

to drive it around to ensure its mechanical intergrity before I rip it

all apart. It also needs a good detail which I will do.

The Del Sol does have a driver airbag and power steering but no ABS (which I dont want). I found a resource online that instructed on how to convert a Miata power steering rack to manual. It involves capping of the hose lines and removing 2 internal seals so the rack movement will not cause internal pressure. I don't know it this applies to the Del Sol steering rack but I will check. There was also a manual rack available that year if all else fails.

Posted: Sun Nov 6th, 2011 01:52 pm

As

is customary, I spent about 5 hours today stripping the old wax off and

polishing the Del Sol. Tomorrow I will finish it up with a coat of wax.

It looks good!

I am really satisified with

the purchase. Yesterday I also jumped the gun and put the stock Honda

engine on craigslist. I found the engine model code (D16Z6) and did a

search. I found a wanted ad that was placed 3 weeks ago and hope that

comes though. I wanted to get a buyer now while its in the car before I

pull it. The engine is a VTEC model, although the 125HP version. The

car gets smogged tomorrow and then Tuesday comes the charger install in

the garage.

I also unpackaged the controller and everything looks great.

Posted: Wed Nov 9th, 2011 02:28 pm

Did alot of measuring and eyeballing. The car got registered and the trunk got all the carpet removed. I am seeing a surprising amount of space. The plan is to keep the roof storage rack installed and mount the batterys below that. I also noticed the back wall of the trunk has 4 threaded bolt holes. This will be usefull to secure items.

Posted: Thu Nov 10th, 2011 12:14 pm

oday

I went to "EV west" and picked up a Netgain Warp9 motor and also a

Level 2 J1772 charging inlet and hardware to adapt it for use on the

Brammo. That's really a side project at this point. If I don't like it

on the Brammo I will use it for the Del Dol, I planned on buying one

anyhow.

@ EVCON a presentation was done and

we where all told that only after about 60hrs of continuous running

does the motor brushes break in. This is an often overlooked procedure

but is cruicial to brush life and motor performance. So I set off to

break the motor in on a test bench with a battery charger @ about

12amps. Sadly my charger could not continue supplying this voltage

without shutting of and resetting once cool. I switched the charger to

it's 2amp setting and the same happened. I guess at this point I will

look for a 12v 10-30amp regulated power supply for this task.

The

guys at EV west where VERY informative and had a lot of great ideas.

Both of the guys where a little tongue in cheek when they said a little

Del Sol with a 160v battery pack and a Warp9 motor powered by a

Soliton1 controller should be a fun little car. I concur.

http://www.evwest.com/

Posted: Fri Nov 11th, 2011 02:07 pm

Today

I went and got a new 12v 2/10/50amp charger. I ended up getting the

automatic model because I will use this for batterys once the motor is

broken in. However because of this feature I am finding it difficult to

get a clean supply of 10amps. It is not sensing a battery to charge so

it wont turn on and supply voltage. I even hooked up a motorcycle

battery to "turn on the charger and limit the power output to the motor

the same that is being supplied by the charger. Long story short that

did'nt work.

And in true geek mode I grabbed a spare 450watt computer power supply, jumpered the green wire and the black wire via a jumper cable on the ATX cable to get it to turn on. I hooked up the connector that supplys 12v. Again it did work but I started to sense the wires getting hot and decided not to start a fire and I turned it off. So again I am looking for a solution. At this point I think a regulated power supply would be a wise investment.

Posted: Sat Nov 12th, 2011 07:38 am

I

went to the local Fry's to source a 12v power supply. I saw a 10amp for

$40.00 but looked cheap. The 20amp model looked solid but was $100.00.

I know this power supply will sit dormant for a LONG time before I used

it again I didn't see the need to spend that kind of money.

As

I left Fry's I did a Craigslist search and found someone 2 miles away

from the store (which was already 15 miles away from home). I swung by

and picked up the 8 amp power supply for $20.00. I figured 8 amp would

be enough because even the battery charger on its 2amp setting would

spin the motor, just not very fast.

I got home and hooked it up an turned the power switch on and NOTHING. I verfied the power supply was putting out electricity, but not enough. So I hooked up the battery charger I had @ 2amp and turned it on. The motor immediatly came to life and I switch off the charger. The power supply just needed a litle boost to get the motor turning. It is now 2 hours into its quest for a 60 hour brush break-in.

Posted: Sat Nov 12th, 2011 10:53 am

OK, correction. As it turns out the power supply slowly ramps up to its rated output in 30second increments. Everything works as it should now, no "jump start" required. I also added a fan to cool the power supply. The motor itself is staying VERY cool.

Posted: Mon Nov 14th, 2011 03:05 pm

Today

I rearranged the garage preparing for the Del Sol teardown. I would

like to finish breaking in the electric motor before I decide to remove

the factory engine. Mostly because I am using the engine hoist to hold

the electric motor. Once that is complete I will lower the electric

motor back down into its shipping box and start with the gas engine

removal. I am currently at 30hours of the 60 recommended to seat the

motor brushes. I am not running the motor unattended. I have faith in

the electric motor however the power supply I am less trusting of.

Because of this I am usually doing 3-4hour run sessions between me

daily activitys.

Always wanting to have 2 irons in the fire I set off to add a J1772 charging port to the Brammo. The only space I could find to centrally locate the port was up above the power button on the "gas tank".

Posted: Fri Nov 18th, 2011 03:21 pm

So no sooner then I got the smart car back from repair did I spend a good 4 hours disconnecting items and draining fluids in the Del Sol. Everything is ready to lift the motor out tomorrow.

Posted: Sat Nov 19th, 2011 08:08 am

I

was generally unmotivated today and spent time doing other things. But

I did remove the full exhaust with muffler and the gas tank including

the hard lines. I can now turn the hot water heater back on with no

fear of blowing the house up.

I did'nt pull the engine even though it looks ready. I am becoming more convinced that leaving the transmission in the car while removing the engine IS possible however it wont be a clean removal and will likely scrap the engine bay up. So at this point I am going to remove them both as 1 unit. The only question now is to drop it out or pull it out.

Posted: Sat Nov 19th, 2011 12:04 pm

Again, I have changed the topic title to be a more accurate

description of the direction its going.

It also appears the GE wattstation charger was the right choice. Both REC solar (major player in solar) and CODA automotive have signed agreements to sell and distrubute the wattstation.

Posted: Sun Nov 20th, 2011 02:44 pm

The engine and transmission are out. Everything went smooth and I ended up lowering the two while still connected to the floor. Next thing that needs to happen is seperate the transmission from the engine and get that back in the car because Tuesday is going to come very quickly. I removed the entire front suspension. And in doing this I noticed one of the original struts was starting to leak oil. Depending on how tomorrow goes I may delay EVWEST coming up until a new suspension setup I have been eyeing is sourced.

Posted: Mon Nov 21st, 2011 04:09 pm

The engine/transmission is split apart and on the ground. I ended up gettting OEM Gabriel style struts as replacements. From everything I have been reading about TEIN and Skunk coilovers leaves me to wonder about the long term durability. If I do end up needing a ride height adjustment due to weight placement I can always getting a higher springrate of the OEM springs. EVwest will be here at 8am to do some measuring for a motor adaptor.

Posted: Tue Nov 22nd, 2011 03:33 pm

The boys and girls from EVwest (the girls where absent) came up from San Diego!

They did alot of measuring and decided it would be best to take the transmission and flywheel with them! So so much for putting the transmission/axels/suspension together while I wait for the plate to be made, really no big deal.

They took alot of time looking at the car and engine bay. They see alot of space to put batteries. And more then once it was mentioned that a warp9 motor and a soliton1 controller was going to be ALOT of fun to drive. While I was waiting on a right size socket to remove the flywheel to be delivered, both the guys took a ride on the Brammo. That was a good time killer as we killed 20 minutes talking about the bike.

IF there is room I have been thinking of running a plate on the back of the motor to drive the power steering,A/C and vacumn pump for the brakes. On the other hand if there is no room I may actually shorten the motor by shortening the armature shaft, that will be the last resort. I think I will be ok with packaging.

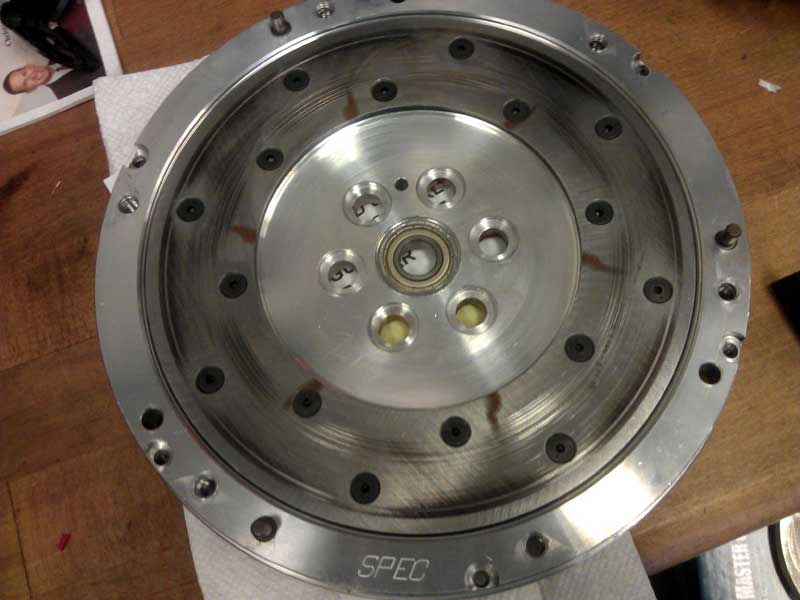

I am going to find little things to do on the car and research a good clutch/flywheel combo. So far a Stage3 SPEC clutch combo seems to be the way to go.

Posted: Mon Nov 28th, 2011 12:57 pm

I called EVWest today to check on the status of the adaptor plate. I was excited to learn that barring any problems they plan to have it done THIS week! I am busy searching around online for the best clutch to use in this setup. I am not worried about it being "streetable" as I plan on not shifting the car very often. The exception to this will be rapid off-the-line acceleration and freeway driving.

Posted: Tue Nov 29th, 2011 01:12 pm

The

clutch has been ordered. I went with a Stage5 SPEC clutch. It is rated

at 505ft lbs of torque. The Stage4 was rated at 300ft lbs and the price

difference was $40.00 to the Stage5. I seriously doubt I will ever push

past 200ft lbs but it is nice to know the failure point WONT be the

clutch.

I have visons of internal gears from

inside the transmission and axle halfshafts spewing alien like green

grease from the CV joints all over the bottom of the car as I apply the

very obtainable 300+ft lbs of torque. No thank you....

A reminder, the original Honda engine was 106ft lbs.

For fun I hooked up the 12v battery to see what things might not work that I have to rewire. Not surprising everything worked except the aux fog lamps and even that might have to do with the relays not being grounded and dangling underhood. The HVAC system commands a valve to open up and let the coolant in the cabin to heat the car, and works normally.

Posted: Thu Dec 1st, 2011 12:40 pm

I called EVwest today to see how progress is being made. The plate itself is done being waterjet milled and they are waiting to source someone to make the keyway in the coupler. It looks like next week will be a more accurate timeframe. They told me if I could'nt wait they could find someone quickly to do the job, however I think they want to find someone to form a business relationship with for future customers. I said no problem and I will continue "geeking" out on the car dreaming up some overcomplicated solutions to simple problems in the name of being different.

Posted: Mon Dec 5th, 2011 02:19 pm

A couple of pictures of why I like this platform for conversion.

A mount on each fender as well as a mount on the subframe.

This is the HVAC controlled valve that lets coolant into the heater core in the cabin.

Posted: Wed Dec 7th, 2011 03:23 pm

I am expected to hear the status tomorrow on the adaptor plate

from EVwest.

I

was getting a little worried my SPEC clutch was M.I.A. I ordered the

clutch from LMperformance.com on the 28th of November and sent them an

e-mail on Friday requesting its status. The website only said the order

was sent to shipping and had'nt changed in 4 days. When I didn't hear

back I called again on Monday and left another message. On Tuesday I

got a voicemail saying the order had left on Monday and would be here

on Thursday, fair enough, I hope that is the reality!

I

am going to replace the front struts tomorrow since they are off the

car. It SEEMS plausible to go ahead and reinstall one side of the

suspension and axle.

As far as steering goes

I am going to take a gamble. A manual steering rack was an option for

this car and is readily available. When I was researching the

possibility of converting a Miata I found a website that gave

instructions on how to convert a power steering rack to manual. This

involved removing some internal seals so the pressure wouldn't build up

when turning the steering rack. It would make sense the instructions

would carry over to the Del Sol but I am unsure.

So basically I am going to try the same thing and I can always

fall back to installing a manual rack at a later date.

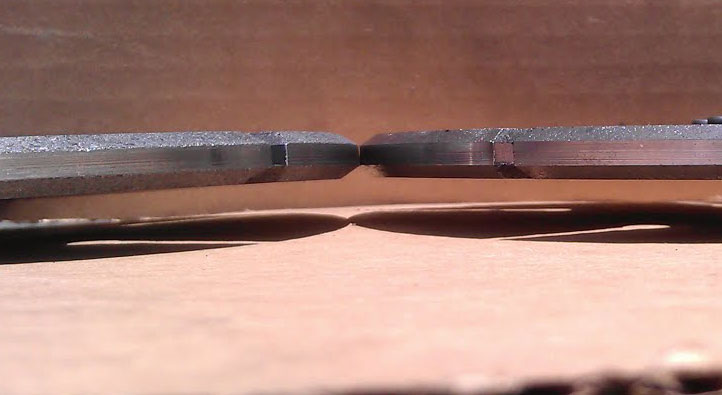

So

I am going to remove the internal seals (see right in picture). Then I

am going to fill the steering rack with as much mineral oil as I can to

act as a lubricant. The 2 steering lines (see left in picture) will not

be blocked off but rather will loop to one another with a small hose.

This is not a money saving tactic as much as it is trying to reuse as

many factory parts as possible.

Please excuse my MS Paint style highlighting.

Posted: Thu Dec 8th, 2011 12:36 pm

The

good news is the SPEC clutch arrived for the Del Sol as promised from

LMPerformance. I ended up going with the SPEC Stage5 setup. I don't

want the weakest link to be the clutch.

The

bad news is I called EVwest and they are now saying the adaptor is 2-3

weeks out! They are still having a hard time finding someone to machine

a slot in the steel adaptor couping.

So again I am going to find other things to do on the car, but honestly I am running out of things.

Posted: Sat Dec 10th, 2011 01:04 pm

I replaced both front struts today. I had them off the car and went to local shops to get a estimate on a simple strut replacement on the struts out of the car. I also had the new struts in hand. First shop said $140.00 and the send shop said $100.00. Not happy with this I ended up doing the job myself. Besides, all I have is time right now until the adaptor plate is ready!

Posted: Sat Dec 17th, 2011 05:16 pm

I

noticed news of Amazon.com now carrying the GE wattstation that I have.

This is great news and opens up another avenue for consumers to obtain

one.

Other then that I have been still

eyeballing the best way of hooking a radiator/heater. Today I noticed

the underhood valve is purposely not totally closed off when valve is

"shut" by the HVAC controls in the cabin. There is a hole in the valve

flapper. That would lead me to believe I could setup a Y connector

before the valve that would loop back to whatever I decide to use as a

radiator. I am not going to get to technical and close off the coolant

flow to the radiator when heat is requested in the cabin.

I

am taking off various brackets that will be reused and removing any

surface rust I see with a wire wheel and repainting them black.

The steering rack continues to leave me thinking. So again I have changed my plan. I am not going to remove the seals in the steering rack. I am going to "loop" the two hoses that go to the front of the car to act as a cooler.

Posted: Sun Dec 18th, 2011 09:34 am

I have often heard there will be a time in the conversion process when you will modify or remove something and realize there is no going back. I guess this happened today when I removed some hard metal lines from the fuel tank to the engine bay. I also took an air grinder and chopped up the stock exhaust/header/catalytic converter. The neighbors who are unaware of my project looked at me with a bewildered look.

Posted: Thu Dec 22nd, 2011 12:51 pm

Just

going back and forth via e-mail with EVWEST to get the rear tailshaft

motor mount made. I found a nice Google sketch up of a mount on https://sites.google.com/site/civicevkit/

I just have to pay EVWEST to input in Solidworks and then they can send to a local waterjet facility. They are closed down until the New Year however.

Posted: Mon Dec 26th, 2011 12:25 pm

I flushed the power steering lines with new fluid. I also put a small hose from the power steering cooler to the inlet of the steering rack. I found that a NPT fitting from a air compressor fit the thread pattern, and I had a spare handy. Its a temp solution until I can get the car on the ground with some weight on the wheels and go from there.

Posted: Wed Jan 4th, 2012 02:27 pm

I ended up talking to Matt at EVwest today. He sourced good Grade8 attachment hardware for the adapter plate. Still waiting on the machine shop to mill the coupler. He expects that to be done on Monday. So things are looking up that next week could be an eventful one. In preparation for that, I still have yet to put the new rear struts on!

Posted: Mon Jan 9th, 2012 01:31 pm

OK I am going to stop posting updates until I get the adapter

plate. Last I heard it is now coming in on Wednesday.

The rear strut replacement is coming along. I had to grind off the lower link bolt that mounts the strut. This is a clean car however its time spent on the East coast took its toll on low hanging metal bits. The rubber bushings are rock hard and need replaced. So right now I am trying to find the best solution. There are some aftermarket pieces have a high BLF (blinky light factor).

Posted: Mon Jan 16th, 2012 03:42 pm

No, I have no update on EVwest. But I have got a lot done on

the car.

I

have the rear struts replaced but am running into problems trying to

remove a bolt I HAD to grind off from into of a bushing on the rear A

arm. Both rear struts seemed really light and easily compressible and

judging by the residue with dirt on the strut I doubt it had much (if

any) oil in the struts, being that they are original.

I removed a lot of undercoating from all the plastic mud flaps

and engine bay trays. The parts look brand new!

I

removed the fuel filler tube which involved a lot of interior trim

removal. And I spotted some poor aftermarket speaker wiring so I redid

that.

I also pulled the wires for the fuel

tank sensor back up into the car and pushed them under the center

console for future use. I don't know if I will need them at all but

figured they are easier to rear in there rather then remove the rear

trim again.

Other then that I took a dry hand brush and got dirt from under the car and it looks really clean!

Posted: Tue Jan 17th, 2012 02:21 pm

Today

was a mixed bag of goodies. I heard from EVwest after I sent them an

e-mail the day before. Everything is done and we are scheduling a time

for them to come back up with the parts and transmission.

Tp

prepare for that I set out on installing the remaining right rear

strut. The bolts where seriously rusted on. I had no other choice but

to grind the bolt off holding the rear A-arm on. So now that makes 2

bolts busted off in bushings I had to get pressed out, on top of the

bushing being in poor condition. And I still have that bushing that is

questionable on the left rear A-arm.

Best thing to do at this point is source some nice aftermarket pieces. My only worry about going that route is the fact that they are aluminum. With the potential added force of batterys and electronics I am more inclined to have good old steel back there! I could care less about saving 2lbs of weight.

Posted: Wed Jan 18th, 2012 01:20 pm

I

am happy to report the plate has arrived! I rotated the motor brushes

in the motor for proper Honda rotation. I just need to find a 1/4

keyway for the coupler and I can put everything together.

On the suspension front I was able to find a A-arm from a local wrecking yard for $25.00. That seems like the way to go for now.

Posted: Sun Jan 22nd, 2012 11:59 am

Baby

steps, the transmission in in and hooked up. The axle are not in

however. I thought about putting 1 axle in the transmission and then

installing it leaving only 1 more to install. But I thought better of

taking a shortcut and opted to install the tranmission and then the

axles later.

The rear suspension has been a

pain! One of the reaining bolts snapped off in the A-arm which left the

remainder of the bolt in the compensator(Honda's word not

mine)/trailing arm. So todays fun and games involved removing that.

Along the line I had to remove the parking brake cable to pull that arm

off. And of course the cable set pin was rusted in and no amout of oil

or cleaning off rust was going to remove it. So I had to grind off the

parking brake cable. Its a good thing I have'nt put the interior back

yet because this is going to make the cable replacement a breeze.

Once

that it complete I still have to get that plate machine for the motor

mount. In the meantime it will just hang with support from the engine

hoist.

YouTube has really helped me out as I was guided and where to

grease the clutch assembly for proper fitment.

I still have to get a keyway but no rush, as I have decided to

get a matching SPEC aluminum flywheel to go with the new clutch.

There is also the matter of finding where the 4-5 wires go from the transmission. With the engine harness off the car, I cannot find the same colored wires on the car. Luckily I still have the harness/engine so it will just take some tracking down.

Posted: Mon Jan 23rd, 2012 01:11 pm

Ever have one of those days there you wish you could do-over?

Well today was that day.

I

set off for LOWES to find a keyway. I needed one 1/4inchx1.25inches

long. I found a 1/4 by 1.5 inches long and just hacked off the excess.

(yes I hate modifying parts to make them fit).

Then I set to mount the coupler and then went on the adapter plate. I was'nt given specs other then "just good and tight". I used 45ft lbs as a figure to work with. This based on torque specs I found of 35ft lbs for the other plate on the other end of the motor. I used 45ft lbs because this was a larger bolt and had more metal to go through. Not to mention if was going to have alot more stress put on it. I put red loctite 271 in the holes and started all the threads. I snugged up all the bolts but on my first pass to torque it to the final value the bolt snapped! UGG! It was a clean break flush on the motor. I called up EVWest to relay the news and they where surprised. They are now sending me Grade8 bolts to replace the Grade5 they supplied with the plate. I went to LOWES again the find an Easy-Out only to find they pulled the stock 6 months ago for an unknown reason and dont have a replacement. So add this hiccup to my list of things to do.

Posted: Wed Jan 25th, 2012 11:26 pm

What to say, what to say.

After

many calls back and forth to EVWest, I think the problem has been

identified. And to make long story short, I dont think it was on my end!

That being said I am taking the motor and adaoter plate to EVwest in San Diego on Friday. They are going to make the repairs and I am to leave with a motor and adapter plate all ready to go. From there I will take it home, bolt in the new clutch and be set to bolt everything together. From there I still need to confirm placement of a rear plate for the motor to act as an engine mount.

Posted: Sat Jan 28th, 2012 03:34 pm

Well,

yesterday I went to EVwest. And for those who don't realize it, I fit

the motor in its big box in the back of the smart car!

So

I got there and they got right to work on it. They ended up snapping an

easy off in the bolt. Then they had to drill out the set screw for the

coupler because they wanted to replace the entire endcap. They did and

they used my original 0mile bearing. However when they got everything

bolt up they became concerned with some measurements. So I had to go

home a verify a couple things. They want to mount up the new flywheel

which chould be here early next week and verify there will be no more

problems. So I left the motor and adapter plate at EVwest.

They

also ordered a GE watstation from LOWES online but for some reason it

came without the grey trim piece on the outside edge. And they are back

and forth on the phone trying to figure that one out.

I got the new rear A-arm in the mail, and this time it is the

correct one!

I still need a parking brake cable and a couple other bits.

Posted: Sun Feb 5th, 2012 07:03 am

I am back in town after being gone a week.

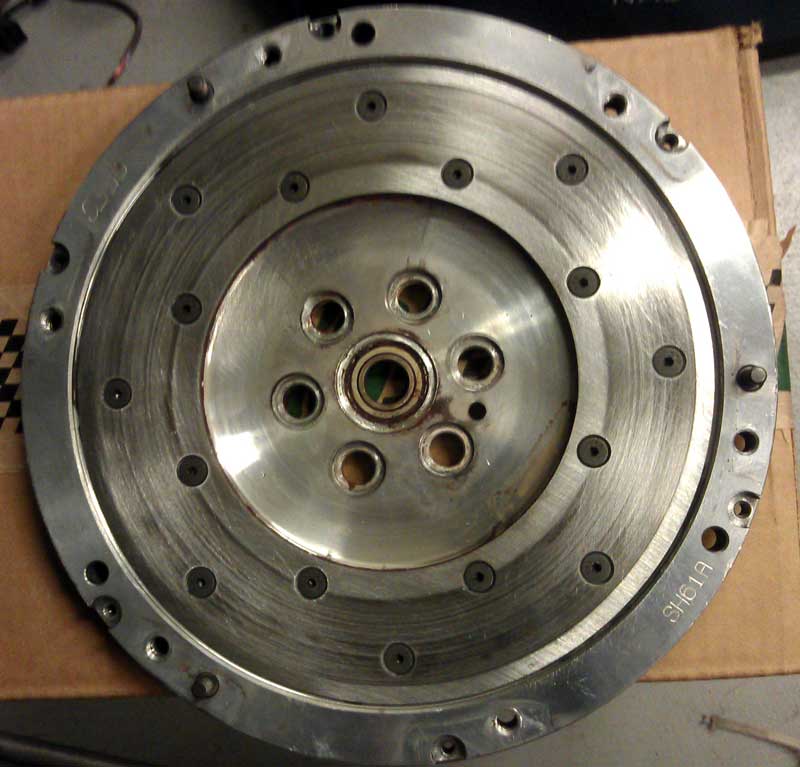

The

SPEC aluminum flywheel arrived. I was worried that through the delay in

time between e-mails to SPEC when I originally contacted them in

December that they might ship a flywheel with the ring gear in place. I

ended up calling them a couple days ago when I was on my trip to

confirm that was not the case. I came home to a nice flywheel set to

bolt up. The shipping weight was noted as 10lbs and I can tell you the

stock flywheel is HEAVY compared to this one. It's my understanding

that reducing rotating mass is good for HP more then TORQUE. And since

this electric motor creates a good amount of torque, that shouldn't be

a problem.

I will take the flywheel to EVwest tomorrow and have them verify fitment. I hope after that I can take everything home and bolt it up!

Posted: Thu Feb 9th, 2012 06:50 am

Not

wanting to leave anything to chance I let EVWest come up and re-measure

the Honda engine. They also brought the motor, the coupler, and adapter

plate and assorted bolts. They replaced the outer ring plate on the

adapter plate with a slightly thicker one. They also now feel it is

required to space out the couple a fraction of an inch with either a

smaller collar/washer. I will wait to get that from them in the mail.

I

expedited the request from EVwest to come up because with the gas

engine up for sale, I have an interested person coming to take a look

at it this weekend.

Rockauto.com came

through with a DORMAN brand right rear parking brake cable that even my

local auto parts shop couldn't even get. And also for $35.00 which is

alot less then the Honda dealer.

Posted: Tue Feb 14th, 2012 09:58 am

As soon as the spacer for the coupler arrived I put it on the

motor and bolted everything back together.

I

was set to finish for the day and I just HAD to get the motor in

yesterday. So I bolted the flywheel up only to have one of the bolts

strip some thread off the coupler. Upon further examination there is

alot more threads that could have been used. So I do need longer bolts

and there is enought thread material left to not be concerned. The

bigger issue came when trying to mate the adapter plate to the

transmission. No amount of tugging or losening of bolts gave me enough

room. By the way, forget trying to drop the motor in from the top.

Although it is possible you will scrape up the engine bay doing it.

Instead I put it in the same way I removed the gas engine. Slid it

underneath the engine bay on a moving blanket and then lifted it up

with a hoist. Come to find out after a step back observation, the

adapter plate is hitting the drivers side axle. So out everything comes

and down to EVwest in San Marcos today to see what could be done. I

thought they might send it out to be milled but instead they ground off

the metal to make space. Now I have to tell you, I had my reservations

about saking a jigsaw and grinder to this nice piece of billet

aluminum. However they did a GREAT job and it looks clean.

So I am now waiting on longer flywheel bolts and I will try

this again!

Posted: Thu Feb 16th, 2012 01:46 pm

While

I wait for the correct sized bolts from EVwest I put the parking brake

cable on and found a rear hub assembly to replace the one with a

snapped off bolt. I ended up finding a clean one off a 1995 Del Sol.

The donar car had ABS and thus had a wheel speed sensor on the wheel

hub. I reused my original hub but this sensor had my mind racing with

ideas. Its a pipe dream but this being a FWD car it gets the

speedometer data from a Vehicle Speed Sensor (VSS)on the transmission.

Imagine having a sensor on a rear wheel that did a comparision to when

was being read on the front wheels. I could see a crude form of

traction control being made rather easily. The fact that I only have a

sensor on one rear wheel does'nt matter as its not a drive wheel.

One of the rubber bushings on this used trailing arm is worn and come to find out this is a common problem. The aftermarket has new metal bushings which eliminate most of the wear problems. I will look into replacements tonight and get some ordered.

Posted: Sat Feb 18th, 2012 08:41 am

After

researching the metal bushings online I decided on going with the OEM

Honda rubber bushing. I popped out the old one out with a hammer and

had a local machine shop press the new bushing in. I will put the arm

on in the next couple days as I find time.

EVwest abondoned the longer bolt search which leaves me to find a longer 12x1.0mm hardened bolts. I have an e-mail into ARP and hope to hear back during the week.

Posted: Tue Feb 21st, 2012 11:40 am

I

have the rear suspension completed. Although I do not have a correct

bolt in the suspension. I never got a replacement bolt for the one I

had to grind off. And I cannot locate the cotter style clip for the

parking brake cable for the brake caliper. It's a matter of leaving

things apart to long before getting it back together, things magically

disappear!

So I am waiting for a bolt, a clip and still need 6 longer

bolts for the flywheel.

Then

along comes the news of lithium battery advancements and the cost set

to drop significantly. I don't know how that will play out in my plans

as battery's are the last thing on my list.

I ordered a digital postal scale that measures down to the tenths. I really like knowing how much weight I am trimming off componants like the steel flywheel.

Posted: Wed Feb 22nd, 2012 12:38 pm

The suspension is back together and the rear wheels are back on the ground. I am still waiting for a quote on remaking a coupler and to hear on the longer bolts.

Posted: Mon Feb 27th, 2012 01:23 pm

The

quest for longer 12x1.0mm bolts has ended. I did not find longer bolts,

looked everywhere. If EVWest has'nt started making the new coupler yet

I may ask for 12x1.25 threads. Those bolts it seems are readily

available everywhere I look.

The scale I ordered came so I found out the aluminum flywheel is 10lbs lighter then the steel OEM Honda variant! However the new SPEC cluch is 1lb heavier then a slightly worn OEM clutch.

Posted: Fri Mar 2nd, 2012 01:04 pm

EVWest

had'nt made the coupler yet so I was able to make the change to 1.25mm

pitch on the threads. They are giving me a 10day ETA on completion.

They are also having the bolt holes taped and threaded all the way

through on this one. They ended up being about a 1/4inch short from

having threads all the way on the "old" coupler.

I am going to hold off ordering flywheel bolts until I have the new coupler in hand.

Posted: Fri Mar 9th, 2012 03:10 pm

I

picked up the new couple today from EVWest. I had a GREAT drive

enjoying the weather, all while semi truck drafting to get 46MPG in the

smart car.

This new coupler is much better

then the original one! The mounting holes are tapped all the way

through, and you can put a longer bolt that does'nt bottom out in the

metal. All while shaving 2oz off the wight of the coupler. The set

screw was also made larger. I found a set screw at LOWES and I ordered

12mmx1.25 ARP flywheel bolts. These bolts have a Under Head Length

(UHL) of 1.0inch vs the .75inch of the original bolts. I hope the have

the bolts early next week.

I will get a picture up shortly.

Posted: Sun Mar 11th, 2012 11:43 am

Even though I do not have the bolts for the flywheel yet, I decided to assemble all I could. Sadly the coupler shaft hole is to tight and by forcing it on, I may have marred up the mating surface. So back to EVwest it goes to get the hole machined larger and the mating surface cleaned up, which may involve removing a small amount of material so I will be back to running that washer to make up the difference

Posted: Mon Mar 12th, 2012 09:33 am

I took the new and old coupler down to EVwest. The tolerences where within 2 thousand. They are going to see about milling a little bit off to make it fit with less hassle, and clean up the marks I put on the face. I heard back from the auto parts place on the flywheel bolts and they are unsure how many the package contains. So I guess I will order them from Summit Racing.

Posted: Thu Mar 15th, 2012 05:33 am

"ARP fasteners" being a local Ca company I decided to order the bolts directly from them. They should arrive tomorrow and I await any coupler news from EVwest.

Posted: Thu Mar 22nd, 2012 02:24 pm

I recent post has brought some attention to the EVTV EVCON

that I went to last year. It's worth a view @ http://green.autoblog.com/2012/03/22/pbs-ev-conversion-convention-DIY-EVCCON-EVTV/#continued

Other

then that I am still waiting for the third installment of the coupler

to be made. I contacted EVWEST and they said it should be done by now.

Also recieved my JLH404AH Ampere hour meter from EVTV and I

can't wait to use it!

And with so many different announcements of battery technology specifically for electric vehicles it leaves me with hesitation. It's not that the $11k for 100 miles worth of batterys is going to be cut 1/3 in price. It's the fact that the battery pack will now go 140-150miles, that is my worry.

Posted: Sat Mar 24th, 2012 03:23 pm

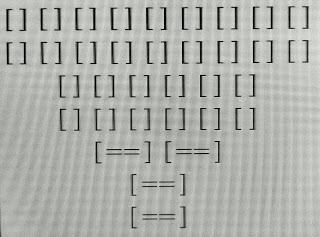

Pictures from the past week. Catching up.

Original coupler on right and revision #2 on the left.

OEM steel Honda Del Sol flywheel weight

SPEC aluminum Honda Del Sol flywheel weight

Posted: Tue Mar 27th, 2012 01:02 pm

Looks like the machine work is done on the coupler but they

want to double check the fitment before I pick it up.

All this is fine as I have my garage full with another car

project at the moment.

I did find a vacuum pump for the brakes! There are alot of options out there but I like the OEM solution as replcement parts are more readily available. The donor car ws a 2002 Audi A4. $75.00 shipped on eBay.

Posted: Mon Apr 9th, 2012 08:47 am

Update:

Life outside my garage has taken a spin in the last week. This has

affected the time I have to work on this project. The next 4 weeks will

have the same outcome.

Ref: http://forum.smartcar451.com/view_post.php?post_id=2014

The coupler at EVwest is complete but they would really like to put everything together to verify fitment. I think that was just a clever excuse to not have me overtorque something or beat on something with a hammer like an ape and ruin the part. That being said, I will bring the motor back down to them and get everything assembled. When that actually happens is a bit of a mystery at the moment.

Posted: Tue Apr 17th, 2012 01:04 pm

I felt good enough today to at least go down to EVwest and have them fit the coupler on the warp9 motor. The coupler fit on with no problem so I brought everything back and will put the flywheel and clutch on as I find the energy.

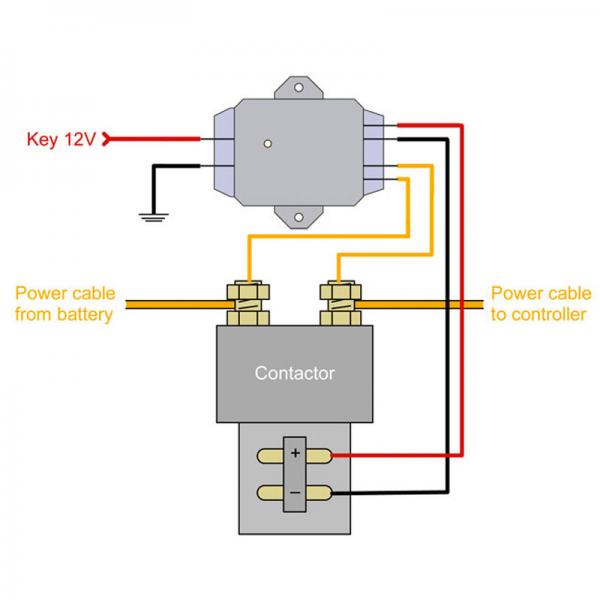

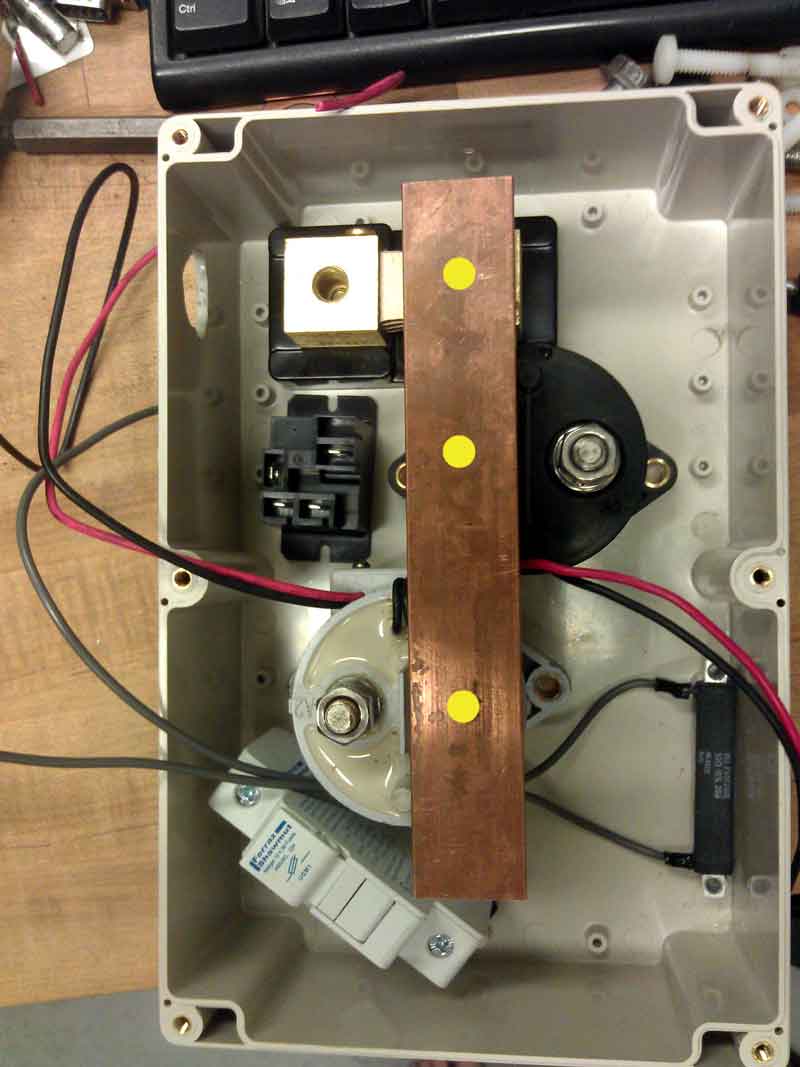

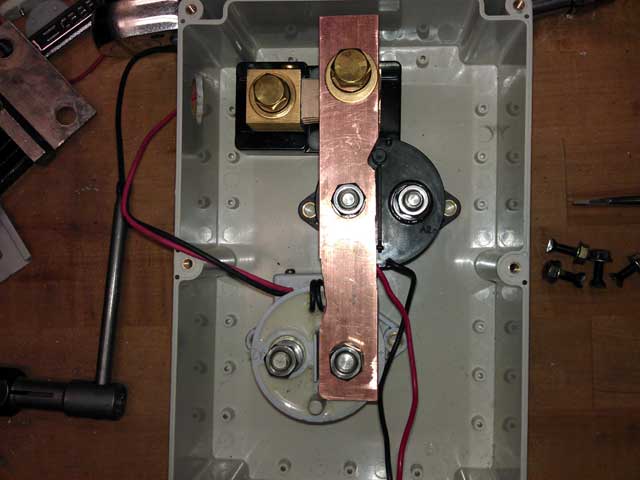

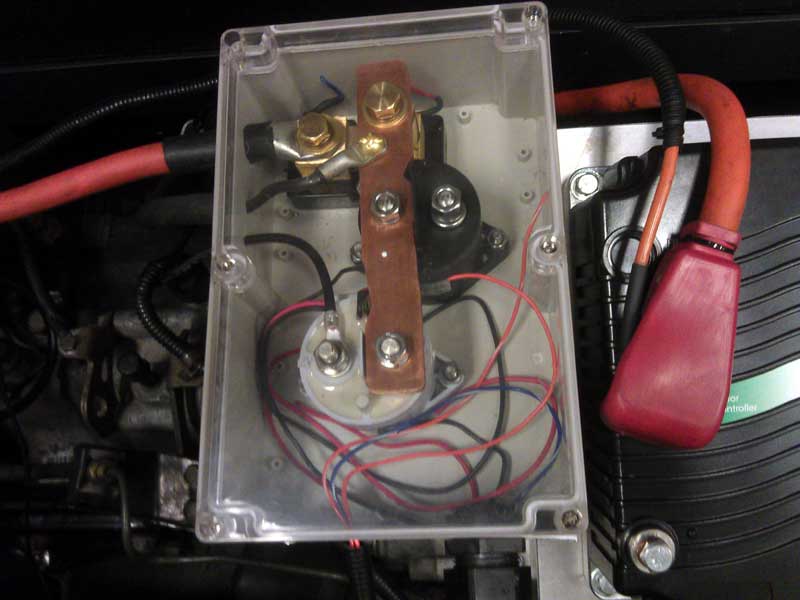

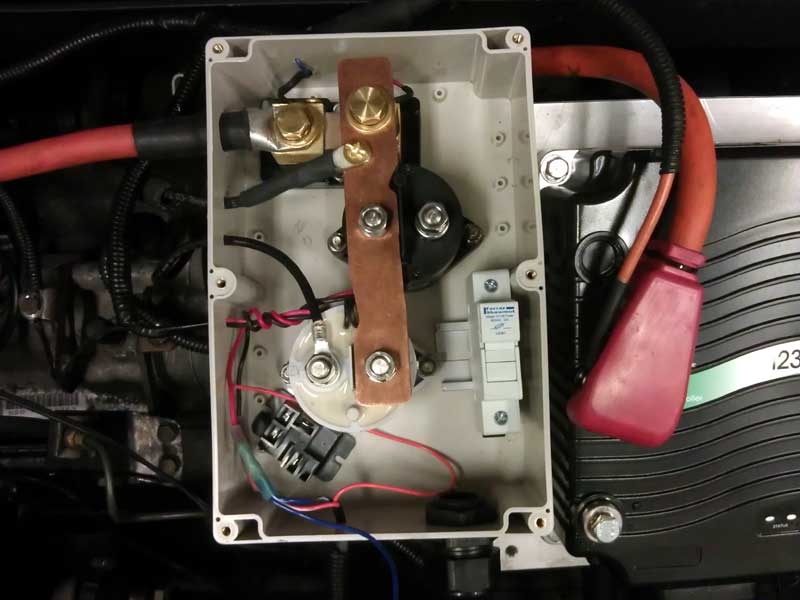

While I was there I also got a tyco contactor and a high

current fuse.

I will eventually need the contactor anyhow to switch on the pack voltage. In the mean time I am going to hook it up once I get the motor in and secured just to make a lap around the neighborhood. Just a mental boost for moral if anything else.

Posted: Fri Apr 20th, 2012 09:32 am

The motor is ready to go in the car. Flywheel and clutch are mounted. I spun the motor on 12v to make sure everything was balanced and nothing appeared out of place. Now I must find the time to get it in the car!

Posted: Sat Apr 21st, 2012 01:51 pm

I have the motor all lined up in the car. The bolts that where provided to secure it to the transmisson are a good inch and a half short. Even then with the plates pushed together it does'nt seem like the spined shaft of the transmission went into the clutch. I wont know for sure until I get it bolted up.

Posted: Sun Apr 22nd, 2012 07:57 am

The transmission is indeed not connecting to the clutch. So again, parts come out and go down to EVwest. This time they want the transmission to which means I have to pull the axles and front suspension. No idea on the time frame that will happen....

Posted: Wed May 2nd, 2012 06:55 am

The removal is slow going as I am trying to recover from a motorcycle accident.

I started the transmission removal today with hopes of taking it down to EVWest tomorrow. That now looks like it will be on Monday.

Posted: Thu May 3rd, 2012 12:43 pm

I found time to pull the transmisssion today. I actually got it completed ahead of schedule and figured I had time to run it down to EVwest. However in my haste I forgot to bring the pilot bearing and clutch fork. They slid everything I had together and the transmssion engaged just fine. I will have more to report tomorrow after I bring the remaining parts.

Posted: Fri May 4th, 2012 02:02 pm

Well now that was interesting, or not!

I brought the clutch fork and slave cylinder down to EVWest. They put it together with no problems! I don't know what went wrong with my install attempt. I did leave everything down there and will pick it up next week.

EVwest is also nice enough to install a support brace

they made for the brush holders as well as a set of H60 motor brushes

that I heard are much harder compound. I got these from George Hamstra

@ Netgain motors who is turning out to be one of many quality people I

have found in the growing EV community.

I skipped out on a TESLA event @ nearby "fashion island" today to get the del sol handled. I am glad I did'nt go. It would have only depressed me with my own project.

Posted: Mon May 7th, 2012 02:21 pm

Here is the brace installed. Simple but effective solution to a problem I don't even fully know exists!

Posted: Fri May 11th, 2012 12:48 pm

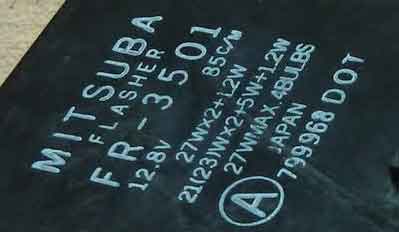

I picked up everything from EVwest today. They did a great job on the brace install and even needed to bleed some batterys so they used my motor with the new brushes which also help seat them in. They also installed a standard temp sensor in the motor which will make finding a monitoring gauge alot easier. Good job guys!

Posted: Sat May 12th, 2012 02:37 pm

The transmission is back in. I am basically right where I was at 3 weeks ago. Although the 4 main bolts I got from EVwest are now correct, there are 4 smaller bolts need to be longer. Adding to the kaos is that fact that there will be 6 weeks of inactivity on the car as I have other things taking up my spare time!

Posted: Mon May 28th, 2012 05:14 am

Just

a little video of the motor running at 12v. I am going to try and work

with EVwest on getting the endplate mount made. Right now its supported

on the motor side by a jackstand!

http://www.techvelocity.com/misc/delsolrunning.wmv

I also made reservations for this years EVCCON in MO! I did'nt register saying I was bringing a car but expect it to be done by then. That website can be viewed at http://www.evtv.me/evccon.html

Which also brings up the fact that in this weeks show they highlighted the benefits of a new rush material rather then the one that came with my motor. The H60 compound is about 7% more effiecent then the old model of brush grade. The other 7% gain is attributed to the split top design which I did not get. To get the other 7% is to spend $200.00 on HELWIG redtop split brushes. So I got halfway there with the H60 compound of the brushes thanks to George @ Netgain!

Posted: Sun Jun 3rd, 2012 04:56 pm

Ever get so excited that a project is nearing comletion that you frantically get it put together to have same some sort of self redemption and/or the frustration level of the project not being completed sooner gets to you. In my case I just got bored and excited when I realized i had a couple of hours to spare.

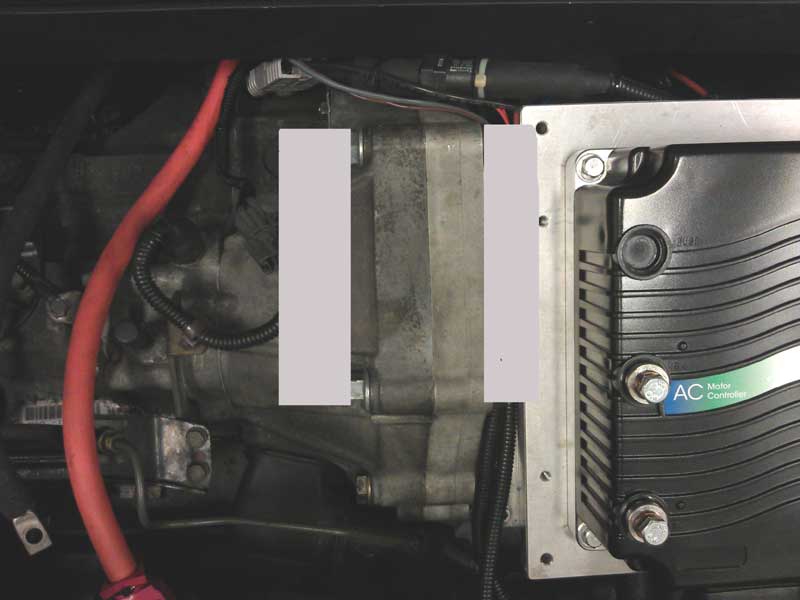

It's a mish mosh of a rig job but I got the vehicle to go forward and reverse for a few feet in the garage by jumping a 12v battery. I am still waiting on the rear motor mount, I still need to get the controller mounted and coolng hoses run, I still need a DC/DC converter and a throttle, oh yeah and 160V worth of batteries, yeah thats about it, I am almost done, NOT!

Posted: Mon Jun 11th, 2012 04:52 pm

I decided to remove the A/C compressor and condenser. I did this because that mount plate I am having made for the motor I will have to have remade to include a space for the A/C compressor. When that happens I will also have to convert from R12 refrigerant to R134A which I would have to do eventually anyhow.

In my haste and more likely due to a female hovering behind me, I cut some crucial wires for the vehicle speed sensor (VSS) that are required to run the speedometer and cruise control off the engine harness I was cleaning up. Luckily I had time to use some already terminated wires off the engine harness to complete a factory look. The female in question also felt bad so I got her involved and she helped cover the wires in electrical tape.

I called EVwest and they are still working with the shop to get a plate made. UGG. The specs called for 1/4 steel and they wanted to go aluminum. Since this is just a temporary solution I told them to stick with steel.

I also decided to avoid certain disaster I am having 12 1/2ft cables made to replace my temporary jumper cables! (remember I mentioned rig job). I placed rubber tubing along the car and routed it in what I though was the shortest and most well protected way I then removed the tubing and measured that.

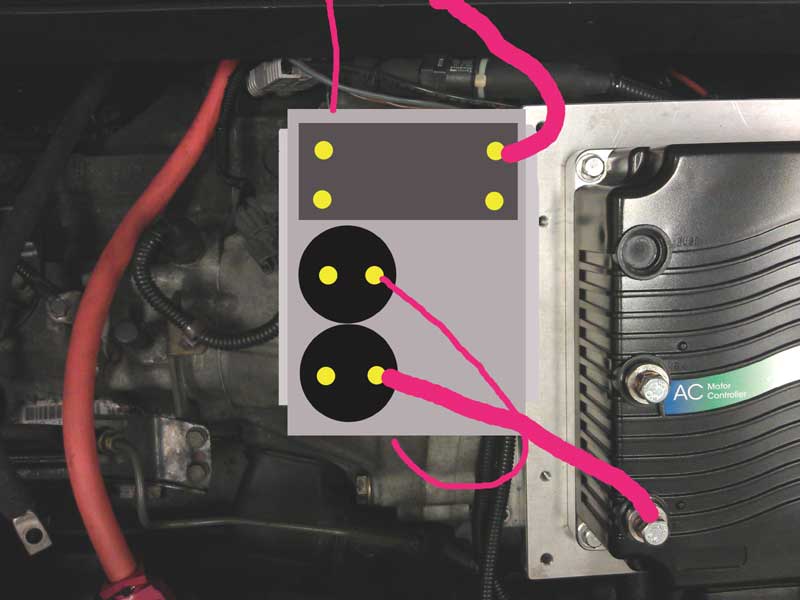

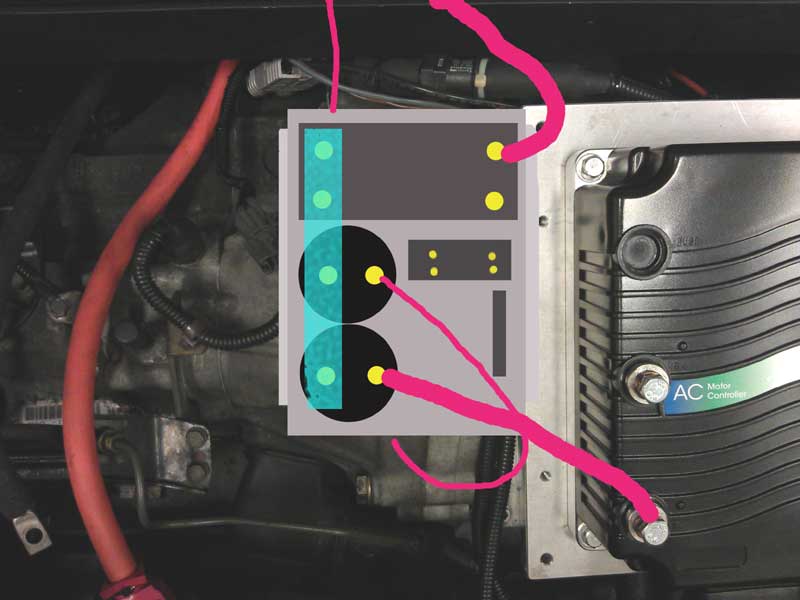

I did think up of a way to mount the Soliton1 controller. I am going to use some angle iron mounted to the transmission bolts. The bolts are long enough to reverse mount the 2 top bolts and then reuse extra thread on the bolt to mount on top of the nut. And if that doesn't work I will just mount it with 1 nut. Mounting it with another nut on top just gives me another inch of clearance. Not knowing how crucial that may be yet. The other end will connect to the motor plate mount.

Posted: Wed Jun 13th, 2012 10:54 am

The rear motor mount is done. I am picking that up tomorrow from EVwest along with a couple odd pieces of angle iron to fabricate a controller mount along with the battery cables. I am also going to see if they have a throttle I like.

Posted: Thu Jun 14th, 2012 05:49 pm

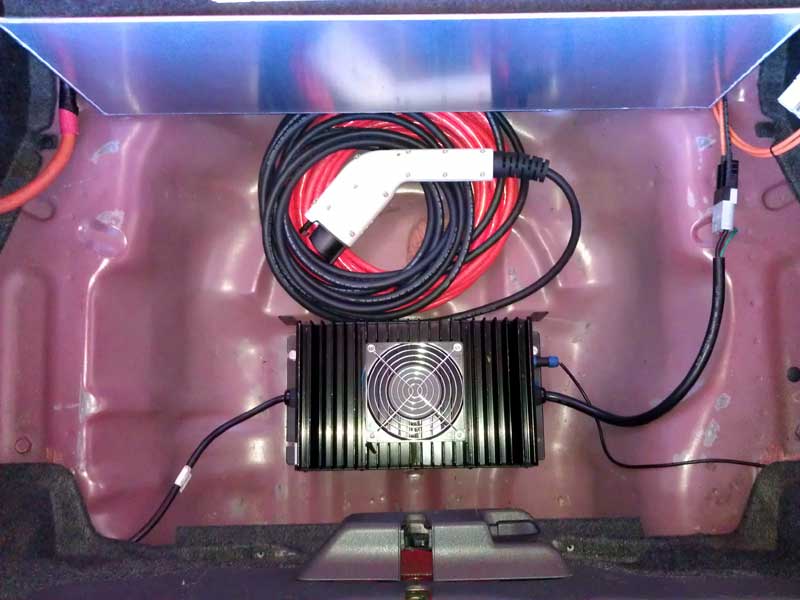

Goodies galore!

From top left. The motor mount I have been waiting for, some angle iron to make a controller mount, an accessory mount I scored off EVwest to possibily mount accessories, and finally the power cable. I will get to installing as much as I can as I find time in the next couple of days.

I did get the mount installed today.

Posted: Mon Jun 18th, 2012 04:44 pm

I

am pretty sure I can fabricate everything I need to affix the motor to

the factory mount and fabricate a mount for the motor controller on the

transmission/motor using angle iron.

This is my first venture in using angle iron and I am growing a fondness to it. Let me describe my idea and then look at the pictures. The mount on the left side (facing car) is simple. I reversed the bolts for the motor mounting plate so the threads where sticking through the left side. This gives me room to secure nuts on the bolt threads. I also faced the angle iron so it is extending to the left. If I don't need this much space I will simply reverse it the other way. So make the mount more level I also removed some metal from the center of the plate so it mounts tighter to the transmission.

On the right side I am using another piece of angle iron but have to space it out as I the plate doesnt cover both the bolts evenly in the OEM engine mount. I then have to drill two holes and have bolts sticking up which will be secured with nuts in the factory mount. Then behind that I have another piece on angle iron facing the other way to act as a mount for the controller. Hard to explain and the pictures once completed will help. Until then:

Posted: Fri Jun 22nd, 2012 04:25 pm

I have the controller plates on and the mount on the motor. Although I am goiing to redo a couple of the angle iron plates because I want a cleaner appearence.

The distance from center to center of the angle iron is the EXACT distance of the controller mounting holes.

I am getting bolts with a finer pitch on the threads.

Posted: Wed Jun 27th, 2012 06:36 pm

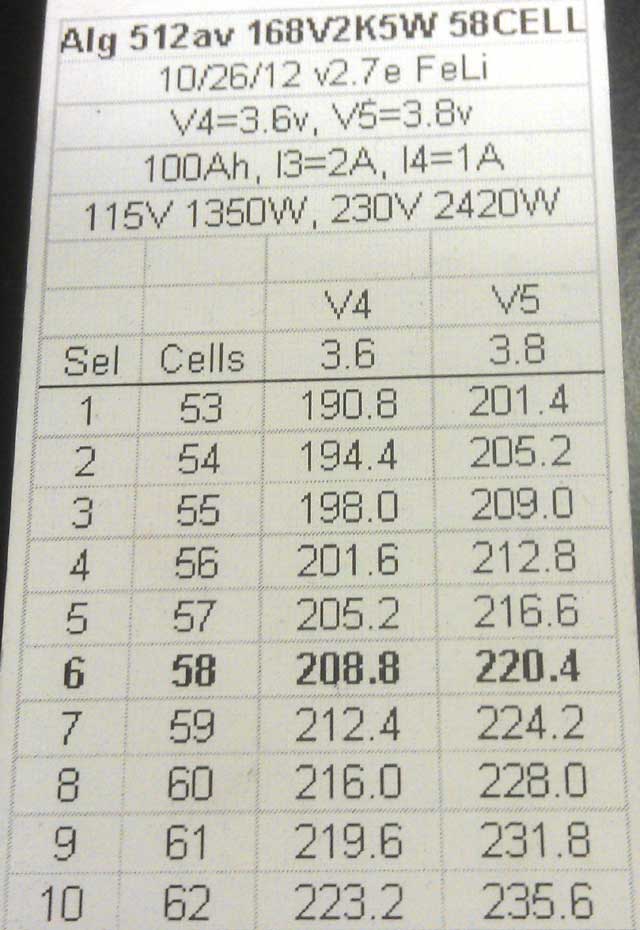

Still fabricating up new mounts for the controller and motor out of angle iron. I have been busy with other projects at the moment. And just when things are winding down and I am about to make the battery purchase news of a revised CALB battery cell is out for the same price. This is the CA series cell rather then the SE. Details of the cells difference can be found on the always informative EVTV blog @ http://jackrickard.blogspot.com/2012/06/battery-jump-shift.html

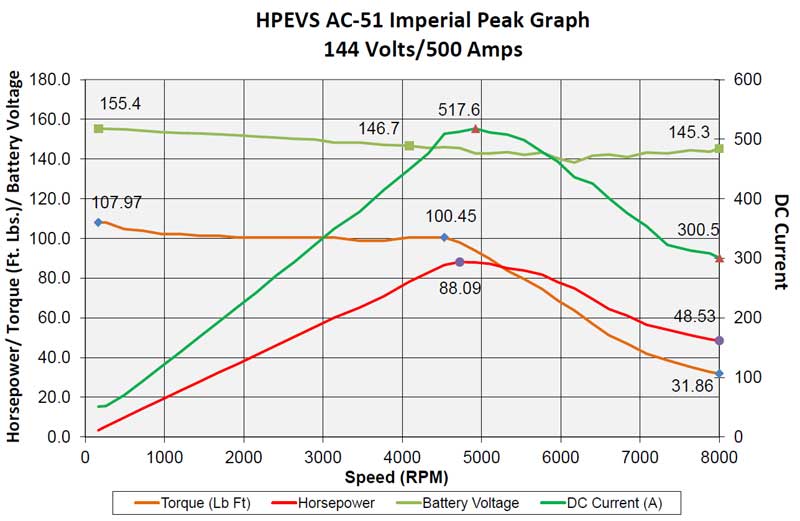

This would allow be to use 58 130ah batttery cells and still have the performance and range I am looking for (1000amps of power and 100 mile range).

With that in mind I did some measurements for the smaller cells and found I could put 4cells wide and 4cells deep between the front strut towers directly over the wheels. This would total 16cells. I then found I could put 20cells behind the seats on the rear shelf directly over the rear axles.

Beyond that I can put more in the gas tank and the spare tire area for the remaining 22cells (58 total).

Posted: Tue Jul 3rd, 2012 05:11 pm

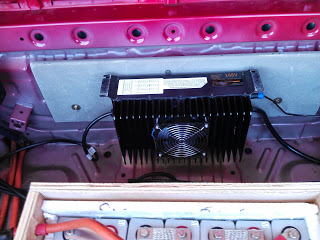

I remade both angle iron controller mounts and am happy with them. This will allow for as big of a battery rack as possible between the strut towers.

I also fitted the controller and am going to look for some allen headed cap screws to affix it to the mount. I am also going to look for a small rubber bushing and/or washer to provide a little bit of vibration resistance. I am unsure of the controller direction because I am most concerned with allowing the maximum amount of coolant flow and prefer straight pieaces of hose to the controller and heater core. And I have no idea why but that controller looks photoshopped in the picture, I assure you its on there! And on the motor mount I ended up stacking 3 nuts on each stud. This was to prevent modification of the factory motor mount. This way a OEM replacement mount would bolt right in with no modification.

Posted: Thu Jul 5th, 2012 03:12 pm

Yesterday on July 4th I finally mounted the controller and got it wired up for power. I am STILL waiting on a tach sensor from EVWEST to spin the motor up. I have to mount the throttle somewhere and am still looking for a clean installation location.

Posted: Sun Jul 8th, 2012 02:24 pm

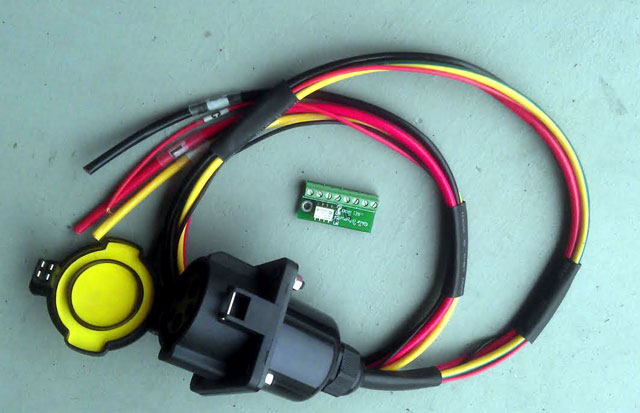

Tomorrow I pick up a tach sensor from EVwest. While I am there I hope to get 2 short cables made from the controller to the motor underneath it. I also purchased a 6 fuse BUSSMAN fuse block and assorted fuses from Amazon. I will use that to provide power to 3 seperate 20amp relays I am going to mount on the firewall. Another small wire will run throught the center console inside the car to a J1772 simulator board which provides the correct handshake signal to turn on most chargers. (Even though I can turn this off in my wall mount GE wattstation EVSE).

This Soliton1 controller continues to amaze me. For having bought this controller 8+ months ago I had feared it may be outdated. True more powerful controllers are out now but this is going to be more then enough for this car. The 3 relays mounted on the firewall will be controlled by the Solton1. 1 for the coolant pump, 1 for the vacumn pump and an optional one for the motor fan if I feel it needs one. This may all get changed around but thats what I am currently thinking. Another idea I had today was running that battery cables through the center console and out holes with gland nuts I would make in the firewall. I had originally planned on running the cables UNDER the car. I am growing more confortable with the idea of them being in the cars cabin. My only concern is the cables as they are routed past the shifter.

I was concerned about the throttle box location as I thought I had to mount a rigid standoff to thread the cables through that would support it as I applied force to the cable. While I am still going to mount a stand off I was happy to learn upon closer inspection of the throttle cable that it already goes through a bracket on the strut tower that provides tight cable support.

Posted: Tue Jul 10th, 2012 02:11 pm

The progression over the last 2 days have been sub par in my eyes. I JUST got the cables today that go from the controller to the motor. (Thanks to Matt from EVwest). But the tachometer was not ready and thus reqiures and extra part to be sent in the mail. On the positive side I estimated the motor cables exactly and are slighty pretentioned in the right position to avoid contact with any metal parts.

Posted: Thu Jul 12th, 2012 11:37 am

That "extra part" I needed arrived today in the mail. Only to find out it is the wrong size. So I waited all this time only to find out I have the sensor for the shaft size I have, IN STOCK the entire time.

So anyways I am wor4ked on the fuse block. The backside iof the block has wiring leads exposed so I made a nice little cover out of spare tinted plexiglass. Rather then try and line of the 4 holes in the fuse block with holes in the plexiglass I just made a large cutout on the inside. It only matters that it seals around the edge anyhow.

Posted: Fri Jul 13th, 2012 05:39 pm

I rewired the backup switch on the transmission so the reverse lights work. I also tapped a wire off of that circuit into 1 of the inputs on the Soliton1 controller. This will limit the power when in reverse. Everything was crimped and had heatshrink placed on the outside inside plastic wire loom. It looks very nice.

I decided to use a piece of angle iron to mount the fuse block on the engine mount. I went into full electrical shock paranoria mode and got nylon plastic screws and bolts to secure it, leaving nothing to chance.

Posted: Wed Jul 18th, 2012 03:41 pm

I installed the tach sensor and updated the Soliton1 firmware. The car now idles but I am looking for a place to mount that throttle and finish up some wire loomes.

I can do small stuff but I will probably hold off on doing anything else big until I get the batterys after EVCON in September!

Posted: Sat Jul 21st, 2012 01:07 pm

Today I finished making the angle bracket to mount the fuse block for accessorys fuses. Adding the first little bit of refinement I decided to throw a quick coat of black paint on it. In the future if I like the look I plan on sending out all the metal brackets to have them hard anodized black. I will put a picture up as I find the time.

The

motor idles off amps but not based on a tach signal. I checked with

EVwest on te wiring diagram and they confirmed my layout as I had

installed it. So I will wait to hear more on that from them.

I confirmed the tack signal is hooked up correctly by telling the Soliton1 controller to have the the #3 output display controller temperature. That corresponded to the tachometer needle indicating about 2000RPM. So I know that is hooked up right.

Posted: Sun Jul 22nd, 2012 06:13 am

The

fuse box all mounted and wired. Just need to get some GOOD (sorry

Harbor Freight) wiring connectors and wire up the individual

accessories.

Posted: Sun Jul 22nd, 2012 05:43 pm

A more up to date photo of the project. The wiring is still rough!

Posted: Mon Jul 23rd, 2012 11:12 am

I made it down to EVwest today. I was able to get the tach sensor tested and it was not working. Matt @ EVwest graciously swapped it out for a working one. I was also able to get a lug for the fuse block cable. I shortened the cable and put shrink wrap on it and it looks great. I have alot of cableing parts on order so when those come in I will wire up the relays to have the Soliton1 turn those on with the controller. OK, enough I's!

Posted: Mon Jul 23rd, 2012 02:10 pm

I couldn't resist! I routed the power cables under the car temporarily (or maybe not?) and took the car out for a test drive! Staying in 1st gear and briefly finding 2nd gear, I made it all around the block which is about 1/4 of a mile. No big deal but it was kind of exciting. Even more exciting was the fact that I was able to get it back in the garage. And the throttle is still not hooked up, I just jacked up the idle to 2500 to drive it around.

Posted: Thu Jul 26th, 2012 03:53 pm

I have cleaned up the wiring alot! Not leaving anything to chance, and even though its only 12v I sealed everything up. On the connectors to the Soliton1 controller I put fork type connectors that have shrink wrap on the connector itself. Then above that I put adhesive shrink wrap over that! And finally the wires are then routed through plastic tubing. I am of course, dreading the possibility of having to rewire and take this all apart but I could only let it look unkept for so long! Beyond that I am waiting for the brake vacumn tank to then complete the fuse block wiring. And I did take the car around the block again just for fun. 24v gets me about 10MPH. And I removed a A/C hard line to give me extra space for the time being.

Posted: Sun Jul 29th, 2012 04:52 pm

I

figured out how I am going to mount the electric vacumn pump for the

brakes. I am going to utilize the original Honda fuel pressure bracket

on the firewall. The mount is already mounted on rubber isolators. I am

then going to drill two small holes and use the pump nozzle and a metal

1'' extension on the back to solid mount it to the bracket. This is the

same way VW orginally mounted the pump . I then went to mount the

bracket for the vacumn tank and it ended up hitting the rear

transmission mount. This was to good to be true as the bracket mounted

perfectly with threaded studs that where already coming from the

firewall!

Other then that I am still finding delight in circling the nieghborhood on 24v for the time being.

Posted: Tue Jul 31st, 2012 11:16 am

Today I set off to mount the brake pump on the firewall. This did not go exactly as planned. As it turns out the diameter of the opening was larger then I felt comfortable with just "filling in" with spacers. And with the said, this is where it got a bit creative. I ended up using chrome plated steel bar stock of a new BBQ rack I found laying around. The bar fit perfectly in the loop on the other side of the mount on the car. I will then string a rubber hose through the bar stock and I get the bends and the length correct. There is a moulded ridge in the mount on the car that I will put a piece of hose on that is split up the middle.

Along with that I had noticed long ago the speedometer not working and just got around to that today. I created that harness and so my first inspection point was to verify the wires integrity. All the wires checked out, and all the connections where secure. However when I went to check the wires I noticed the ground wire was a 5V signal. Not knowing if this was correct I grounded it for the time being sandwhiched in between a bolt head and a washer that goes to the frame. Everything I found online indicates this should be a body ground which would be 12v. I will check that on my next "outing" around the neighborhood. I was always unhappy with the way the vehicle speed sensor (VSS) went together when I had it off the car months ago. Worse case scenario a new VSS off eBay is $8.00

Posted: Tue Jul 31st, 2012 12:33 pm

That ground wire was the problem with the speedometer. Everything performs as it should now. Now the question is just ground the wire where its at on the frame somewhere or redo and whole 3 wire harness and ground it closer to the VSS. In testing I made 8 big loops around the neighborhood. I hit an ASTONISHING 20MPH in 2nd gear. (laf)

Posted: Thu Aug 2nd, 2012 01:29 pm

OK before you laugh, this is merely a case of function over form!

I have pride myself with taking the time to have everything laid out neatly and tidy under hood. This one instance however blows it all away (I hope not)!

So I got the pump bracket made, used the

sharper "starter" section on a much larger drill but to start the hole

and then I finished it with the correct size. The chrome surface proved

to smooth and the drill bit wanted to wander. There was very little

room for error as the metal bracket was about 1.5x bigger then the hole

I needed to drill. So that was done and I marked and sliced a hole in a

piece or rubber hose and slid it over the bracket. The pump did not

want to go into the mounted without hitting the metal part of the OEM

bracket. I solution was devised of simply flipping the pump upside

down. But now without the housing acting as a collar the pump could

hypothetically fall out. The fitment was secure and tight enough that I

didn't see this as even a remote possibility but I decided to error on

the side of caution. I took a small rubber strap I had laying around

the garage and wedged it between the pump and the firewall backet. I

then routed the strap under the pump and put tension on it. At this

point with the other end I flipped it over the pump bracket and safety

wired the strap onto itself. I then cut off the excess rubber.

The

pump is powered but a 15amp fuse on my fuse block. The power is routed

through a relay which is controlled by the Soliton1 controller. Right

now I just have it power on with the controller but I plan to hook it

through the vacuum switch on the vacuum tank once I find a place to

mount it. I have also been toying with the idea of having the

controller command the pump relay when the brake pedal is pressed. This

would be AFTER I wire the controller for a brake signal. I had avoided

this because I believe by default the controller is disabled when the

brake pedal is pressed. And right now with just idling around the

neighborhood at 2500RPM I kind of need to depress the brake pedal when

going up the driveway.

The pump is powered but a 15amp fuse on my fuse block. The power is routed through a relay which is controlled by the Soliton1 controller. Right now I just have it power on with the controller but I plan to hook it through the vacumn switch on the vacumn tank once I find a place to mount it. I have also been toying with the idea of having the controller command the pump relay when the brake pedal is pressed. This would be AFTER I wire the controller for a brake signal. I had avoided this because I believe by default the controller is disabled when the brake pedal is pressed. And right now with just idling around the nieghborhood at 2500RPM I kind of need to depress the brake pedal when going up the driveway.

Posted: Fri Aug 3rd, 2012 03:48 pm

I spent entirely to much time today rewiring the main 2 power cables through the passenger cabin. Not happy with the small round plug that the Del Sol has just below the glove box on the firewall, I set off to create my own. I found a nice oval stamped impression on the firewall near that hole. And when I set off to create this I first drilled a large hole and then filed out the space I wanted. This is time consuming but I have learned that although I love power tools, mistake can happen fast! At least this way I have time to correct myself before straying to far. The neighbors where probably taking up a collection for an air grinder as this filing went on for about an hour. And to protect the cables I filed off all sharp corner of the opening and then split thick rubber hose and cut it perfectly tofill in the hole. This is until I get EVwest or someone to cut off the ends by the controller, slide the gland nuts off and slip them on the other side of the cable and then back through the firewall.

I totally spaced on when I had these cables made. I had them put the gland nuts already on the cables, which leaves me no way of taking the nut off to thread them. Then I have the cables routed so that I cant open the center console lid all the way. I fixed this by routing them a different way. However the one thing I cannot fix (I think) is the door for the radio not opening all the way. It comes close and I can operate all the buttons on the radio, but I know it opened farther. I also spent entirely to much time getting grease off of the cables from being mounted under the car.

While I was there with everything opened up I took the time to open the condenser airbox and vacuum out a lot of leaves! I then took a wire through the OEM plug in the firewall and ran a wire to the ECU in the passenger footwell. I am going to piggyback the signal for the brake switch to send to the Soliton1 controller.

Posted: Sat Aug 4th, 2012 11:46 am

Just

for fun I wired up the brake pump to a 15amp ignition feed and took the

car around the block. I now know why this pump is meant for

intermittent use, as it was hot to the touch after the drive. I hooked

up the brake input signal off the ECU to the Soliton1 input and from

there it goes to the pump relay. I little bt of extra wire there but

until I know where everything goes I will leave it. As a positive the

brake switch is always hot so I can leave me foot on the brake before

turning the ignition on and it builds up enough pressure for the first

initial brake depress until the pump comes on. This is all until I

mount the vacuum tank.

Speaking of which to prepare for that I turned the pump around in the bracket (easier said then done) so I had more space to mount that tank right next to it.

Posted: Sun Aug 5th, 2012 04:56 pm

The

pump is mounted temporarly, although it is in the position I plan plan

to use. Luckily I made good use of my vast quantities of metric nuts

and bolts that I have amassed throughout the years! I drove around with

the brake signal I stole from the ECU triggering the brake pump. This

was all yesterday. Then today I hooked up the signal so it goes through

the pump switch before triggering the pump. This circuit is always hot

by default. So this works out good, before or as your turning the

ignition key on, depress the brake pedal and in 3 seconds you will have

a full tank.

I also made a starter cover out of sheet aluminum for the

transmission.

Going through the ECU pinout diagram I found 2 more signals I want to tap into. One being the malfunction imdicator light (MIL) and the engine coolant temp (ECT). I will tap into those in the coming days.

Posted: Tue Aug 7th, 2012 04:25 pm

There

has to be days like this to! Upon finally finding some good 16 guage

wire, I wired up the MIL and the temp guage. In testing however niether

work. I will look into that more tomorrow. I was able to find the

coolant tank that another online vendor uses as part of a cooling

package. They refused to tell me the part number so after a quick

search on Summit racing's website I found the DORMAN part # with a cost

of $6.00. I do have to drill and tap the plastic tank for a couple

barbed nipple fittings but it seems like a small price to pay.

On another note I think I hurt one of my 12v batterys from loading it to much or perhaps it was the cycling that did it. I now have a fully charged pack voltage of 21v instead of 26v. I do seem do remember a small puff of vapor coming from the battery in question.

Posted: Thu Aug 9th, 2012 12:07 pm

I

am a bit confused on the direction I want to go with the coolant

overflow tank. If I where to use it a a "surge" tank like I had on a

couple C5 Corvette's it would require the coolant be under pressure, I

believe 5-6PSI. Unsure if the overflow tank can take that under

repeated use, or even how how this coolant is going to get. And if I

use this as a true overflow tank using the stock radiator is the

coolant EVER going to get that hot with that much coolant capacity to

utilize it.

At this point I am going to hook

up the tank and drill it for 1/2'' fittings drawing coolant using a

larger fitting replacing where the current pipe is molded into the

plastic. I will then put the "return" fitting halfway up on the tank. I

am even rethinking that as I dont want bubbles to be created by the

return that the gets sucked into the inlet pipe. Maybe both fittings

side by side?

And the dash temp guage and MIL light not working may not be an issue. I cannot get the controller hot enough to register a temp @ 24v (well now maybe 20v). And I am not so yet inclined to take a heat gun to the controller so I may just let that go for the moment. I am still unsure if the MIL should be illuminated when I disable the controller. So until a real error come up I dont know. I may try and set the battery rabge out of spec to try and throw a light.

Posted: Sun Aug 12th, 2012 02:41 pm

Just

playing around today. I removed 1 nut from each motor mount studs I had

sticking up for the dog-bone engine mount on the drivers side

fenderwell. This made the motor and controller perfectly level! I am

still leary about how course the threads are but I think it will be

fine.

I replaced the 15amp fuse for the vacumn pump with a 5amp. After repeated use it finally blew. I then went with a 10amp variant and that seems to be holding nicely. The spec called for 15amp but I timed it and the 10amp fills just as fast so I figure less is better.

Posted: Mon Aug 13th, 2012 12:35 pm

Finally got the tank mount finalized. I still wish it did'nt stand off from the firewall as much. The way around that would make a longer plate and bolt the tank directly to that. It would be off center by a couple inches with no support behind a portion of it.

Posted: Sun Aug 19th, 2012 07:37 pm

I

shortened up a few wires under the hood (I can't call it "engine bay"

anymore) and re-routed them for a more cleanly appearence. I am going

to try and get the small pin blade type connectors from a local Honda

dealer so I dont have to splice together to a pre terminated connector

wire. I did end up grounding the VSS locally to a ground bank on the

firewall and avoided a long wire connection.

And I did find another place for the vacumn tank if its current location does not work out. Yes, it involves the use of more angle iron, WAHOO!

Posted: Mon Aug 20th, 2012 01:28 pm

I think I know how I am going to route the throttle cable! Yes, it involves angle iron. I am going to make a new motor mount and extend the angle iron out by about 5 inches (Black rectangle in photo). This is the best solution I have found. In doing this it does not bend the cable any more then stock. It will also require a very short run of 14-15 inches of wire to the controller.

Posted: Tue Aug 21st, 2012 02:45 pm